Air Protection

Overall, air emissions totaled 1,498 tonnes in 2014, including 160 tonnes of solid emissions and 1,323 tonnes of liquid and gaseous emissions in the reporting period.

|

Substances |

Volume, tonnes |

|---|---|

|

Total emissions |

1,498 |

|

including solid substances |

160 |

|

including liquid and gaseous substances: |

1,323 |

|

sulfur dioxide |

91 |

|

carbon oxide |

578 |

|

nitrogen oxide (rebased to NO2) |

208 |

|

hydrocarbons (net of volatile organic |

58 |

|

volatile organic compounds |

366 |

|

benzopyrene |

1 |

Air protection measures include:

- controlling the harmful content of vehicle exhaust emissions to prevent impermissible excess values;

- adjusting vehicle fuel systems and replacing gasoline systems with gas-powered systems;

- renovating and landscaping land;

- putting into operation dust-collecting units for woodworking machines.

Some branches of SDCs took measures to justify and develop sanitary protection zones (SPZs). These measures were intended to reduce the adverse impact of the noise generated by the cooling systems of supply transformers (substations rated 35 kV and above) and the exhaust gas emitted by the Company’s vehicles near residential areas.

Water Protection and Conservation

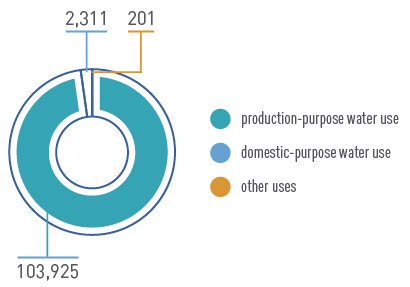

Overall, water withdrawal in the reporting period increased by a third to 106 million cbm. Most water came from surface sources (103 million cbm), and a relatively small amount came from underground sources (1,100 cbm) and other sources (1,800 cbm). All water was mainly utilized for production purposes.

Water protection and conservation measures generally dealt with:

- exercising compliance control with respect to maximum permissible concentrations of contaminants in effluents in sewerage and storm drainage systems;

- repairing drainage systems in a timely manner to prevent insufficiently treated effluents from coming into sewerage systems or ground water;

- improving drainage systems;

- cooperating with specialist organizations for the receipt and treatment of effluents;

- controlling the condition of the treatment facilities of vehicle-washing plants;

- installing new filters and chemical agents at closed-water-cycle vehicle-washing plants.

Land Protection and Conservation

One of the Company’s significant measures of environmental responsibility is compliance with environmental safety requirements for electrical installations in the design phase. For example, oil receivers and drainage systems are used to protect soil from oil products.

The reporting period saw a considerable decrease in damage to land (from 15.8 hectares in 2013 to 0.47 hectares in 2014). All damaged land was rehabilitated, except for 1.29 hectares to be treated in 2015.

In addition, the Company deals with production waste. Waste treatment measures generally dealt with:

- disposal;

- transferring production waste to specialist organizations for subsequent processing and dumping;

- setting limits on waste disposal and providing equipment for temporary waste storage places.

In 2014, the Company generated 112,000 tonnes of production waste, including 218 tonnes of ash and slag. Most waste (109,000 tonnes) was transferred to contractors for disposal and dumping. A portion of waste (1,300 tonnes) was decontaminated. Therefore, 2,500 tonnes of waste remained untreated at the end of the year.

Technical Measures

The main area of grid organizations’ activities is various technical measures, including the operation of electrical installations and other equipment. In its technical activities, the ROSSETI Group takes into consideration environmental issues.

Some technical measures aim to protect soil from oil products. For instance, repairs are carried out to oil receivers and drainage systems in 2014. Oil-filled equipment (circuit breakers) is replaced with vacuum equipment. Additionally, oil-filled supply transformers rated 6–10/0.4 kV are gradually replaced with oil-filled sealed and dry transformers. The construction and repair of cable lines use modern cables with insulation made of cross-linked polyethylene and heat shrink tubing, which eliminates the use of lead.

The Company gives particular attention to bird protection in building overhead lines. The new construction, rehabilitation, and re-equipment of overhead lines rated 1,000 V and below use self-supporting insulated wires. In addition, 6–20 kV protected-wire overhead lines are built, which decreases the area of cut-over land and protects birds from an electric shock. Insulation is installed for exposed current-carrying parts of substation busbars.

Bird protection equipment, including visual and acoustic repellents, is installed in large bird habitats and migration paths. This equipment is primarily installed in nature reserves and sanctuaries. In the construction of new power facilities, the Company no longer uses towers with pin insulators in large birds’ nesting areas.

In the reporting year, the ROSSETI Group purchased and installed 25,556 bird protection equipment units.

Another environmental initiative of the Company is to install noise screens in 110-kV substations to reduce noise in residential areas in accordance with SanPiN.

Pursuant to the Stockholm Convention on Persistent Organic Pollutants, the Company implements the phased schedule of disposing of hazardous trichlorodiphenyl-containing equipment for 2013–2025.

In 2014, the Company disposed of 4,815 capacitor cells with a total weight of 208.7 tonnes:

- IDGC of Centre: 128 cells with a total weight of 5.5 tonnes;

- Kubanenergo: 283 cells with a total weight of 14.4 tonnes

- IDGC of Siberia: 270 cells with a total weight of 16.2 tonnes

- FGC UES: 4134 cells with a total weight of 172.6 tonnes.