Operations of ROSSETI and its SDCs do not involve a material adverse environmental impact that can lead to environmental disasters or cause any irreversible change to wildlife. Environmental safety requirements applicable to electrical installations are established in the equipment design phase, including the need for the protection of soil from oil products (construction of oil receivers and drainage systems under oil-filled equipment containing more than 1 tonne of oil), for the protection of people and animals from exposure to current-carrying part (prevention of unauthorized touch or penetration), etc.

Key Goals of Environmental Responsibility

The development of the procedure for implementing voluntary mechanisms of the Company’s environmental responsibility and the necessity for the regular publication of Russian Grids non-financial reports are set out in Directive No. 1710p-P13а of March 30, 2012, approved by Russian Prime Minister Vladimir Putin.

The goals and objectives of ROSSETI’s environmental responsibility are contained in the guidelines and ruling documents prepared and constantly updated at the level of SDCs. The key areas of protecting the environment against the adverse impact of operating activities of the distribution grid organizations managed by ROSSETI are set forth in the Programs of Environmental Policy Implementation specifying environmental protection measures in the areas listed below:

- air protection;

- water protection and conservation;

- land protection and conservation;

- technical measures;

- resource conservation and energy efficiency enhancement.

Environmental Protection Initiatives and Current Programs

Air Protection

Air emissions totaled 1,498 tonnes in 2014, including 160.11 tonnes of solid emissions (11%) and 1,323.07 tonnes of liquid and gaseous emissions (89%) in the reporting period, namely:

- 91.28 tonnes of sulfur dioxide (6.9%);

- 578.12 tonnes of carbon oxide (43.7%);

- 207.78 tonnes of nitrogen oxide (rebased to NO2) (15.7%);

- 57.66 tonnes of hydrocarbons (net of volatile organic compounds) (4.4%);

- 366.14 tonnes of volatile organic compounds (27.7%);

- 0.60 tonne of benzopyrene (0%).

Air protection measures include:

- controlling the harmful content of vehicle exhaust emissions to prevent impermissible excess values, adjusting vehicle fuel systems, and replacing gasoline systems with gas-powered systems;

- renovating and landscaping land;

- putting into operation dust-collecting units for woodworking machines.

Some branches of SDCs where the key adverse factors were the noise generated by the cooling systems of supply transformers in the case of substations rated 35 kV and above that were located near residential areas and the exhaust gas emitted by vehicles in the case of motor depots located near residential areas worked to develop and justify sanitary protection zones (SPZs).

Water Protection and Conservation

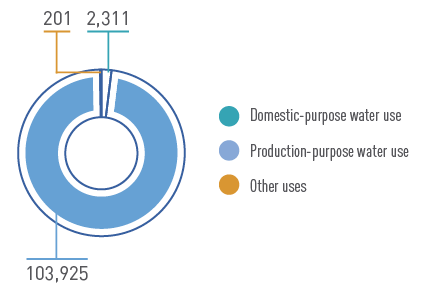

Overall, water withdrawal in the reporting period was 106,178 thousand cbm (132% up). Most water came from surface sources (103,208 cbm, or 143% up), and a relatively small amount came from underground sources (1,112 cbm, or 12% down) and other sources (1,786 cbm, or 10% down). 106,429 thousand cbm of water was mainly utilized for production purposes (103,924 thousand cbm).

Water protection and conservation measures generally dealt with:

- exercising compliance control with respect to maximum permissible concentrations in effluents in sewerage systems;

- repairing drainage systems to prevent effluents with exceeded maximum permissible concentrations from coming into sewerage systems or ground water;

- improving drainage systems, complying with laws with respect to making payments to specialist organizations for the receipt and treatment of effluents;

- controlling the condition of the treatment facilities of vehicle-washing plants;

- installing new filters and chemical agents at closed-water-cycle vehicle-washing plants, etc.

Land Protection and Conservation

In 2014, the Company generated 112,048 tonnes of waste, including 218 tonnes of ash and slag. 2,476 tonnes of waste remained at the end of the year. Waste treatment measures generally dealt with:

- disposing of production waste;

- transferring (entering into agreements for the transfer of) production waste to specialist organizations for subsequent processing and dumping;

- setting limits on waste disposal and providing equipment for temporary waste storage places.

Most waste was transferred to outside organizations (108,883 tonnes) in the reporting period, and a portion of waste (1,328 tonnes) was decontaminated.

The year 2014 saw a considerable decrease in damage to land (from 15.8 hectares in 2012 to 0.47 hectares in 2014), all of which was rehabilitated. Only 1.29 hectares of damaged land remained at the end of the year.

Technical Measures

Technical measures are the main area of grid organizations’ activities: the operation of electrical installations whose specifications, requirements, and characteristics comply with the applicable legislative acts, including with respect to environmental issues.

The focus in 2014 was on the following measures:

- oil-filled circuit breakers were replaced with vacuum equipment that does not contain oil products contaminating land;

- repairs were carried out to oil receivers and drainage systems, and a disposal was made of trichlorodiphenyl-filled static compensator battery cells pursuant to the Stockholm Convention on Persistent Organic Pollutants to ensure their safe operation, decommissioning, and disposal without causing harm to people.

This equipment is disposed of in a phased manner according to its technical condition and depending on planned replacement and disposal expenses. A phased draft of the schedule for disposing of capacitor cells was made for 2013–2025. Disposal of static compensator battery cells in 2014:

- IDGC of Centre: 128 cells with a total weight of 5.5 tonnes

- Kubanenergo: 283 cells with a total weight of 14.4 tonnes

- IDGC of Siberia: 270 cells with a total weight of 16.2 tonnes

- FGC UES: 4134 cells with a total weight of 172.6 tonnes.

Payments for permissible and above-level emissions, effluents, and waste disposal are made; compared with 2013, such payments remained the same (a reduction of 717,000 rubles), due to the timely preparation and approval of permits at most SDCs, thus avoiding fivefold payments, and totaled 45,675,000 rubles;

- new construction, rehabilitation, and technical upgrading of overhead lines rated 1,000 V and below use self-supporting insulated wires and 6–20 kV protected-wire overhead lines are built, which decreases the area of cut-over land and protects birds from an electric shock;

- new construction in large birds’ nesting areas does not use towers with pin insulators; bird barriers are installed;

- bird protection equipment and insulation for exposed current-carrying parts of substation busbars, including visual and acoustic repellents, were mainly installed in large bird habitats and migration paths.

Overall, the Company purchased and installed 25,556 bird protection equipment units, including as follows:

- IDGC of Center and Volga Region in 2014 purchased 4,800 bird protection equipment units for overhead lines of its branches Marienergo, Nizhnovenergo, and Udmurtenergo. First, bird protection equipment is installed on overhead lines located in conservation and wildlife areas. The total number of bird protection equipment units installed on 6–10 kV overhead lines of IDGC of Center and Volga Region is 20,264, which made it possible to provide equipment for about 500 kilometers of lines;

- Under the program, IDGC of Volga in 2014 purchased and installed 8,677 bird protection equipment units for Ulyanovsk Distribution Networks, 496 units for Chuvashenergo, and 1,362 units for Samara Distribution Networks;

- IDGC of Siberia in 2014 completed measures to install 1,800 bird protection equipment units on 6–10 kV overhead lines.

Noise screens installed in 110 kV substations reduce noise in residential areas to the maximum permissible limit in accordance with SanPiN. The rehabilitation and re-equipment of oil-filled supply transformers rated 6–10/0.4 kV is accompanied by their gradual replacement with oil-filled sealed, dry transformers, which makes it possible to minimize oil product spills contaminating land. The construction and repair of cable lines use modern cables with insulation made of cross-linked polyethylene and heat shrink tubing, which eliminates the use of lead.