A top priority of the Company’s policy toward its employees is to reduce the risk of occupational injuries. ROSSETI keeps on improving the occupational safety management system and enhancing our industrial safety methodologies and processes. The Company systematically collects and analyzes accident information and, based on this analysis, makes decisions to minimize injury risks.

In addition, the Company is active in communicating with various audiences in order to reduce injury risks that may affect outsiders at electric grid facilities. ROSSETI employees work in cooperation with law enforcement agencies to protect power facilities from equipment theft and prevent unauthorized network connections – these offenses are a frequent cause of injury and death in outsiders. The Company also takes preventive measures to reduce the risk of electrical injuries that may affect people.

To achieve these goals, the Company issued in 2014 the order “On Measures to Reduce the Occupational Injury Rate,” approving the Program of ROSSETI to Reduce the Injury Risks of ROSSETI SDCs’ Personnel and Outsiders at Electric Grid Facilities for 2014–2017 and the Model Comprehensive Program of ROSSETI to Reduce the Injury Risks of ROSSETI SDCs’ Personnel and Outsiders at Electric Grid Facilities for 2014–2017.

The year 2014 saw 61 occupational accidents at ROSSETI, involving 67 people.

Number of Accidents

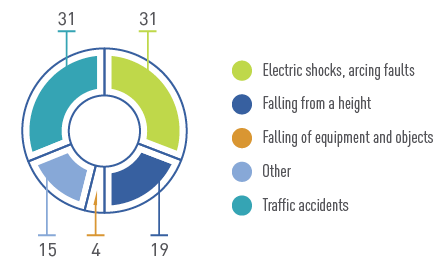

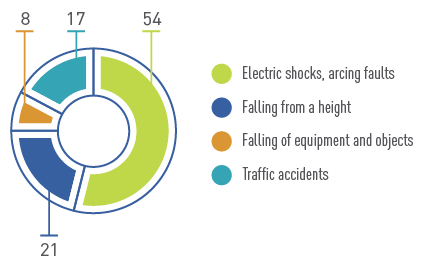

In 2014, the indicator of electric shocks and arcing faults affecting personnel operating electrical installations decreased by 11% compared with 2013 to 31%

The main cause of injuries in 2014 was electric shocks and arcing faults affecting personnel operating electrical installations.

The most frequent causes of accidents were as follow:

- failure to comply with technical regulations prescribing the switching-off and grounding of current-carrying parts of operating electrical installations; failure to use personal protective equipment while approaching ungrounded current-carrying parts;

- negligent handling of operating energized equipment.

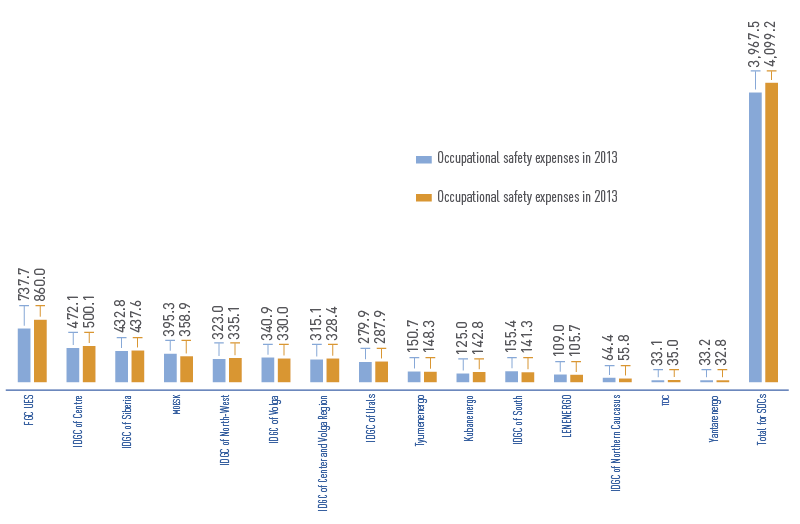

Increased occupational safety costs prove that efforts in this area are important to ROSSETI SDCs.

The total occupational safety costs of SDCs were 4.1 billion rubles in 2014, or 3.3% more than in 2013

The Company is determined to continue its increasingly strenuous efforts in occupational and industrial safety to minimize injury risks affecting its employees and outsiders.